For instance, predictive maintenance analysis could be used to automatically send alerts and notifications and feed relevant data to ERP maintenance modules, which would enable maintenance orders to be scheduled, stock inventory to be checked and personnel requirements to be automated. Using 5G and Satcom connectivity, data analysis can also take place in the Azure cloud compute platform. During the demonstration, the Microsoft Azure Stack Edge Mini R – a computing device– was used for computing and analysis onsite. With O3b mPOWER, the bandwidth can be scaled from 100Mbps to a Gigabit depending on the requirements of the mission.Īzure services can be used to display live position and analytical data on a dashboard in the field.

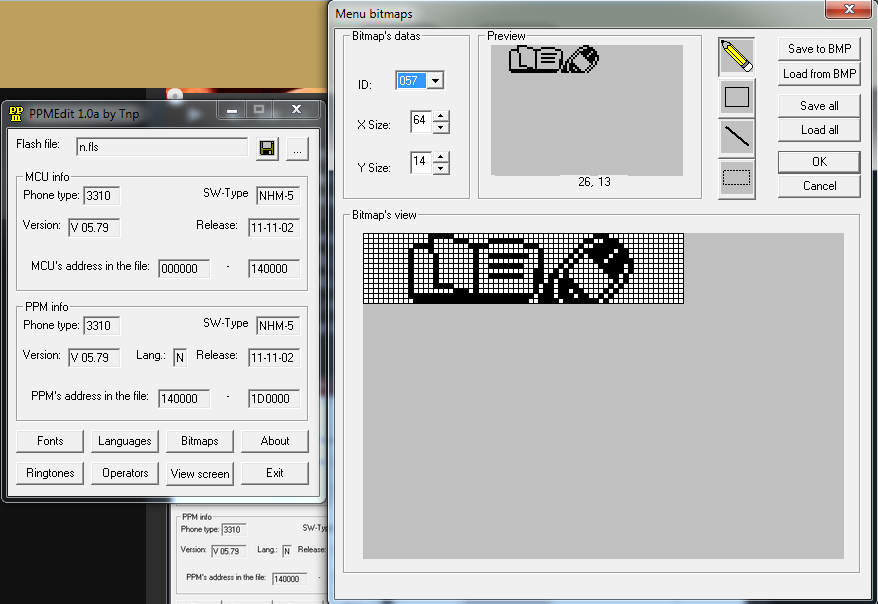

#NOKIA TEXT EDITOR DOWNLOAD DOWNLOAD#

In this demonstration, download and upload speeds reached 348Mbps and 67Mbps respectively. The system can provision throughputs up to multiple gigabits per second per service. Orbiting at approximately 8,000km above Earth’s surface in medium earth orbit (MEO), the O3b system delivers connectivity. Improved access to data also opens opportunities for automation and optimisation of back-end processes, such as predictive maintenance, stock management, fleet management, and operational budget forecasting.įor the demonstration, SES – an Azure orbital ground station as a service partner – showcased the potential data transfers by accessing its O3b satellite constellation via transportable terminal antennas. Through real-time ERP updates in the field, logisticians and commanders located at headquarter sites can make decisions based on tactical data on vehicle fleets.īoth raw and processed data can be sent from vehicles in the field to enterprise systems over Satcom when the operational situation allows to increase commanders’ awareness of deployed assets.

0 kommentar(er)

0 kommentar(er)